The Single Strategy To Use For Plant Conveyors And Systems

Table of ContentsPlant Conveyors And Systems - TruthsPlant Conveyors And Systems for BeginnersThe Facts About Plant Conveyors And Systems RevealedPlant Conveyors And Systems Can Be Fun For AnyoneExamine This Report on Plant Conveyors And SystemsPlant Conveyors And Systems Things To Know Before You Buy

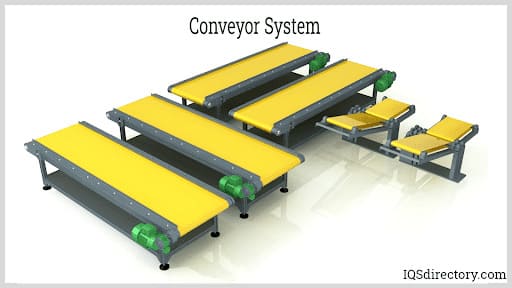

Carryback is typical in all belt systems and also is just one of the significant issues that causes belt breakdowns. Drive: The drive for the belt can be situated in different positions in the communicating system. For many belt conveyors, the drive is situated at the discharge or head of the belt - Plant Conveyors and Systems.AC motors are generally used to power the pulley that moves the belt. Chapter 5 Conveyor System Applications As automation and also manufacturing have actually come to be a lot more highly advanced, conveyors have quickly created into an important part of product handling as well as activity in addition to improving the speed of different production procedures.

Conveyors transportation the item into the high temperature level heaters for the sintering procedure. Product packaging: A packaging conveyor is made to aid with item packaging, such as positioning completed products in containers, reliable labeling, or prep work of products for delivery. The function of a packaging conveyor system is to relocate items from completion and setting up for delivery.

Getting My Plant Conveyors And Systems To Work

Press out conveyors are made use of to eliminate molded pieces from the pushing line or on various other operations. Airport: Though flight terminals have individuals relocating conveyors, the main conveying system is for baggage handling, which accelerates the procedure of getting travel luggage from the checkin counter to the plane and off the airplane to luggage pick-up.

Though mining conveyors differ in size and also size, the majority of them get on an incline and relocate a number of lots of material. They have to be equally packed to stay clear of spillage or voids. Depending upon the layout, they operate extremely swiftly up to 100 fpm. Mining Conveyor Automotive: The auto sector uses a number of selections of conveyors for product handling.

The one element that makes them special is the requirement to satisfy governmental guidelines for hygiene and sanitation. Printing: Printing conveyors, for display printing, use a conveyor dryer procedure for drying screen printed material. There are other methods for drying screen prints, conveyor dryers are used for large quantity manufacturing and also come in numerous selections.

How Plant Conveyors And Systems can Save You Time, Stress, and Money.

The usage of conveyors has led to greater quantity, enhanced manufacturing, and also avoidance of injuries. Regardless of the market, conveyors have actually been verified to be a boost for manufacturing processes.

Continual Operation: Products are continually loaded and also unloaded for long durations of time without interruption or blockage. Automated Unloading: Conveyors can be designed to immediately dump materials without the demand for manual work. Control of Activity: Conveying systems have rate controls to keep track of how swiftly items move along the system, which removes the issue for handling problems or breakage.

Some Known Facts About Plant Conveyors And Systems.

The photo listed below is of a security cord pick up conveyors. High Quantity: Conveyors are a component of an automatic system qualified of moving hundreds or thousands of lots of material per hr or in a day. Phase 7 Conveying System Malfunctions There are breakdowns that can take place in a conveying system that is constantly in usage.

Conveying System Malfunctions Mistracking Mistracking is additionally called belt drift, where the belt wanders to one side. A misaligned belt can seriously harm the belt by uneven wear or more information damages things on the belt. The image below is of a belt that has wandered to the. Confiscated Rollers Part of the mistracking issue may be related to a taken roller, which can cause sharp edges that would close down the system.

Slippage Slippage on a belt conveyor can happen because of stress being as well high or low, which can read more bring about stretching and conveyor belt slippage. Clog Conveyor systems are designed to run continuously without disturbance or interruption. Any type of kind of blockage can be harming to the system as well as cause significant repair services.

Examine This Report about Plant Conveyors And Systems

The most usual is when material adheres to the belt as well as goes past the transfer point and also diminishes. Carryback can be seen at the bottom of the picture below. Splilling When a belt conveyor is overwhelmed, or as well jam-packed, products can diminish the sides. This can happen when employees are not trained properly, or there is an issue up the line.

The image below is of product develop in the line. Screw Conveyors Exhaustion in a screw conveyor happens when there is construct up in the pipeline as the conveyor turns. There is always a gap in between the wall surface of the pipeline and the blades of the screw. Because void, material accumulates and also hardens.

Indicators on Plant Conveyors And Systems You Need To Know

Repair or visit this page Replace Making the decision to replace a part on a system has numerous price factors, such as the downtime for the system, finding the best part, and employing an expert to do the replacement. This expense can be offset with routine maintenance and tracking of the system. Electric motor The crucial part of a conveying system is its motor (Plant Conveyors and Systems).

Bearing failing can be credited to lubrication problems. This can be prevented by having a routine maintenance cycle for bearing maintenance. The temperature degree of the motor should never ever surpass its advised operating temperature level. Sheave Bearings Pulley-block bearings are completely loaded with lubricating substance to shut out water and also contaminants. They never require fixing if they are regularly examined and preserved.